A-Line E.D.S. (Environmental Decommission Service), based in Waterloo, Iowa, provides environmentally sound decommissioning of transformers and associated electrical equipment and comprehensive transformer recycling and removal services.

A-Line tracks detailed information about each piece of equipment and how it moves through the handling process. Previously, the A-Line team was using pen and paper to document information on load sheets as equipment was unloaded, and then they’d manually type all of that data into Excel.

Jennifer Bridges, Inventory Lead at A-Line E.D.S., explained, “Our previous manual process included handwriting all the information that we were gathering as our warehouse crew unloaded our inventory and then typing the information into an Excel ‘load sheet.’ That file was used for reporting to the lab to match up oil samples to the correct units and to our office for invoicing purposes.”

The handwritten approach offered flexibility because the team could take pen and paper anywhere they were working—internet access or not—but it had many downsides.

“It was a bulky system when it came time to enter data in that we had to type all that information into our server separately, and when we were busy, that extra step slowed the rest of the process down,” said Bridges.

“Two of the biggest challenges had to do with the double entering of data and the consistency of some of the data being recorded,” Bridges said. “Having to re-enter data that we took down out in the field slowed down the reporting process, especially on busy days when we are unloading trailers one after the other and did not have the chance to sit down at our computers.”

As the company grew and brought on more people, handwritten log-in sheets were inconsistent since each person had their own logging style and notes.

“We needed a system where the data would be recorded in a consistent style from the start of the process to cut down on the amount of time it takes to go through each load sheet and enter the data electronically,” said Bridges.

They also needed a system that had fewer human errors and less risk for data loss. Entering data manually from handwritten notes offers endless opportunities for human error. And a shared Excel file, even in Sharepoint, can be accidentally overwritten or changed, causing untold data issues.

“We had been using the same pen and paper method for 14 years, and that had been working well for us,” said Nicole Littlefield, Lab Manager at A-Line E.D.S. “But there was the hope that we could streamline getting the information from the unloading process in the warehouse to the billing process in the office.”

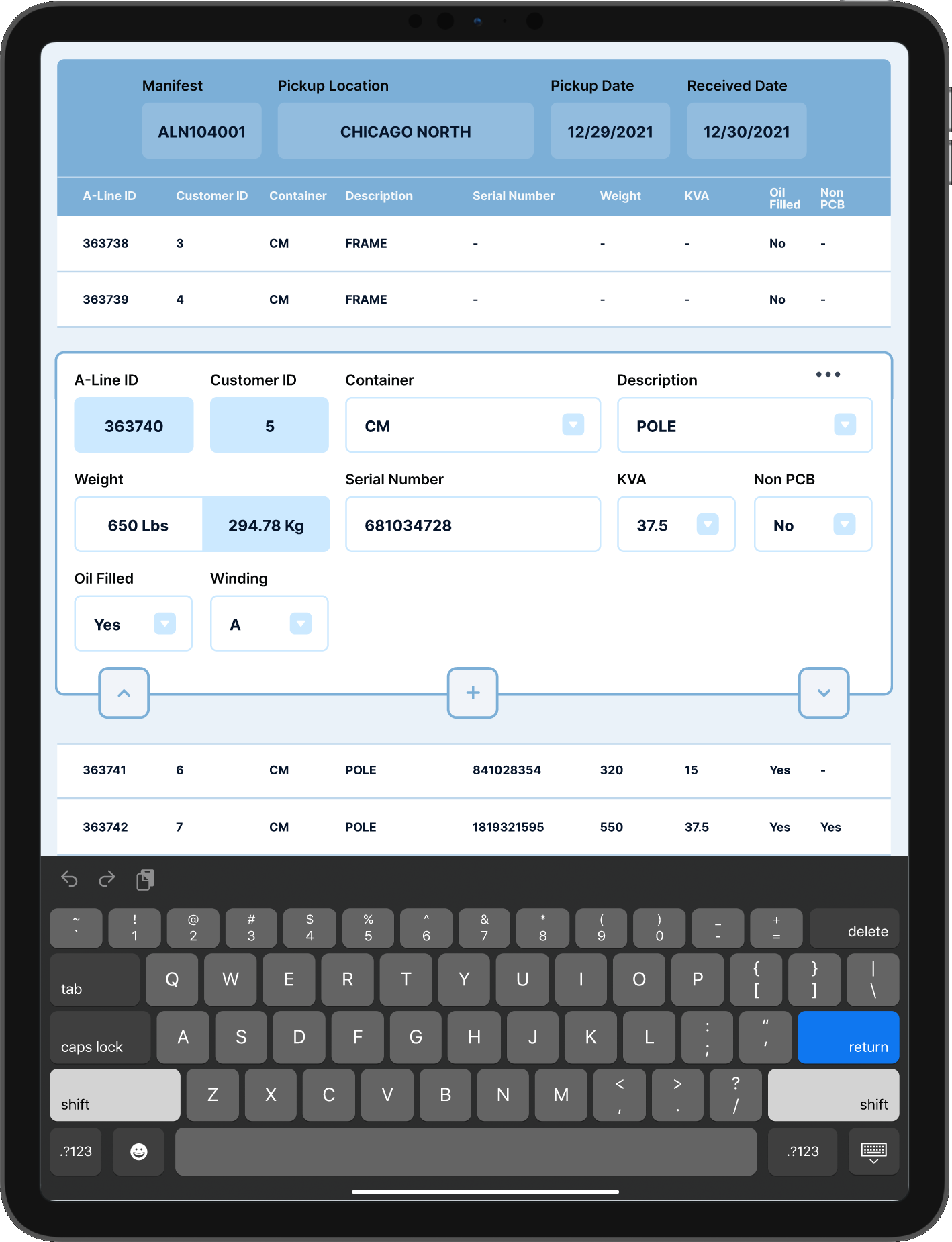

After thinking about whether to buy or build, A-Line E.D.S. decided to work with Far Reach to build a custom software solution that allows the equipment coming in to be documented electronically, instead of with pen and paper. During the unloading process, team members use a tablet to record information right in the custom platform—no more handwriting to interpret or digitize after the fact.

“By recording our information digitally, we no longer need to worry about whether we are reading another person’s handwriting properly, which really helps cut down on errors and corrections,” said Bridges. “The drop downs and typing inputs make entering the information a little more efficient, helping to decrease the time it takes to record information on each item we are logging in.”

By understanding A-Line’s needs up front, we knew they would need a system that’s easy to use on all types of devices, especially tablets. So, we built a responsive web-based application that can be used on desktops, tablets, and phones. The A-Line team can login from anywhere—for example, when working from home—something impossible with paper processes.

“We are also very happy with being able to transfer that information into our load sheet system,” said Bridges. “The time and effort that step alone has saved us has been a tremendous help.”

While A-Line evaluated software as a service (SaaS) solutions, custom software was the right move. When organizations have custom processes, especially ones that are well defined, custom software can fit into those processes instead of having to rework processes to fit a SaaS platform.

“Custom software was right for us because when we were making this transition, we wanted it to be as painless as possible,” said Littelfield. “There are so many people inside and outside our company who need to use the information we are recording. Changing too much of the style or language of that system would be confusing for us and our customers.”

“It just made more sense for us to have a software program that was able to adapt to our needs rather than our process changing to fit an already established software,” Bridges said.

Does your business have custom processes? Custom software could be the right solution.

Download our guide to see.

It can be hard to find an outsourced software development partner that’s a good fit. As a local company, A-Line was able to meet the Far Reach team in person, and the Far Reach team was able to go on-site at A-Line to see their manual processes in action. This in-person connection is by no means necessary for a successful partnership, but in this case, it was an added benefit.

“It has been very helpful to be able to tell the Far Reach team what we are looking to accomplish and then have the software mirror as much as possible what we’ve already been doing—but also allow us to improve parts of that process,” said Littlefield.

Thanks to established manual processes, A-Line had a good idea of what they wanted and needed in a custom system. The transition to a digital platform also provided the opportunity to identify and make improvements to those processes at the same time.

“Because we were trying to be both consistent but also trying to make many improvements to our processes, this has been a very big trial and error project for us,” said Bridges. “The Far Reach team has been great about listening when we tell them what we need to accomplish, taking that information in, and coming up with a system that has helped us do what we need to do to provide our colleagues and customers with consistent and accurate information while helping us to be more efficient by streamlining the process.”

A-Line set out on the journey of developing custom software for many reasons—process improvement and more reliable data management being core to the decision. But the shift to a digital platform was also part of their plans to scale. With multiple locations and a growing customer base, A-Line can only handle as much equipment as their processes allow. By using custom software to become more efficient, they are setting themselves up well to meet future growth goals.

The custom software system can grow and change as A-Line does. They have full control over upgrades, new features, additional integrations, and more—something they wouldn’t get with a SaaS platform.

Moving from paper to digital processes comes with many challenges, but the A-Line and Far Reach teams worked together to build a custom system that makes a difference.

Littlefield said, “They have been so patient and attentive to our concerns and our feedback, and they have really worked to help us fine-tune the program into what we want. It’s been a very good experience.”

Do you have paper processes ready to turn digital?

Reach out.